Machining

Machining conditions and tooling have been specially developed by Sandvik, enabling Sandvik to supply CNC and/or EDM machined components.

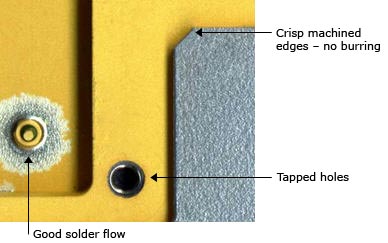

Machined details in CE11 package

Machined details in CE11 package

Machined details in package made of Osprey® CE11F alloy.

Typical tolerances for machined CE alloy components supplied by Sandvik

Dimensional

Dimensional tolerances depend on the machining method used:

- CNC: +/- 0.05mm typical

- EDM: +/- 0.02mm normal

Flatness

Normally 1 in 1,000 but up to 1 in 10,000 can be achieved if required.

Surface finish

- Normal finish after milling Ra < 1μ

- Normal finish after lapping Ra = 0.4μ

If required, a finer finish to Ra = 0.02μ can be achieved by polishing.

Threading

Low Si alloys (Osprey® CE13F and CE17F) can be tapped to any size. All Si alloys can be thread milled down to as small as 0-80 UNC.