Design guidelines

Osprey® CE7F and CE9F controlled expansion alloys exhibit attractive properties for many thermal management and electronic packaging components.

Examples are low coefficient of thermal expansion (CTE), low density, high specific stiffness, thermal stability, flatness and high thermal conductivity. However, these materials are relatively brittle and therefore the design of components must be carefully controlled to achieve optimum results.

Generally, normal design rules for CNC machining should be followed for the CE alloys other than for those features covered by the guidelines below.

Read more about machining of CE alloys

Holes

Avoid positioning holes very close to the side walls of packages and to the edges of tags or plates; e.g. allow at least a 1mm wall surrounding the hole.

Avoid positioning holes very close to the side walls of packages and to the edges of tags or plates; e.g. allow at least a 1mm wall surrounding the hole.

Threaded holes

Threaded holes down to 0–80 UNC are possible to machine.

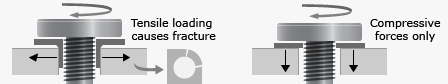

Bolting down of plates

Use a plain washer rather than a bush insert so as to prevent cracking (see below).

Radii

External radii

External radii

External radii are generally not required (although they can be machined with ease) and will add to cost, because 'starting' blocks are normally cut with square sides. Parts can be chamfered if necessary.

Internal radii

Internal radii

Large radii are desirable (e.g. 0.5 to 0.75 mm or greater) in order to reduce machining cost.

Tags

External tags

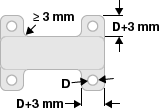

Minimize the use of hold-down tags if possible. However, if tags are necessary, ensure that they are reasonably thick (>1mm), that they have large internal radii (typically >=3 mm) and are at least 3mm wider than the holes in the tags.

Minimize the use of hold-down tags if possible. However, if tags are necessary, ensure that they are reasonably thick (>1mm), that they have large internal radii (typically >=3 mm) and are at least 3mm wider than the holes in the tags.

Thickness

Wall/base thickness

Generally, a thickness of walls/base >1 mm is recommended, although thinner walls can be incorporated provided that the wall height is <5 mm.